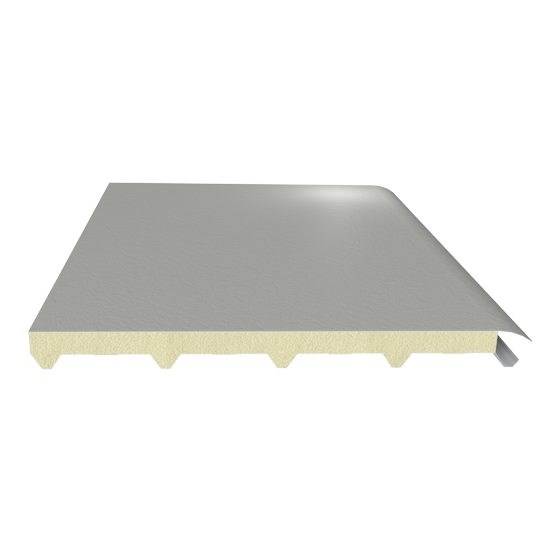

Membrane Roof Panel | N5M

Please click on "Offer Request" button below to send your offer and detailed information request to the company for the Membrane Roof Panel | N5M product.

• Industrial Buildings

• Military Buildings

• Public Buildings

• Agricultural Buildings

• Sports Facilities

• Construction Site Buildings

• Silos

• Hypermarkets

• Shopping Centers

• Storehouse Halls

• Administrative Buildings, and all other concrete structures with steel or prefabricated load bearing systems.

• PUR/PIR; Surfaces (Prepainted Galvanized Steel Surface,Aluminum Steel Surface, PVC Membrane)

• PUR/PIR (Polyurethane/Polyisocyanurate Density (EN 1602) PUR: 40 (±2) kg/m3 / PIR: 41 (±2) kg/m3

• Polyurethane/Polyisocyanurate Thickness 40-50-60-80-100 mm

• Thermal Conductivity (EN 13165) 0,022-0,024 W/mK

• Dimensional Stability (EN 13165) Level DS (TH) 11

• Reaction to Fire (13501) B. S2 . d0/B.S1.d0

• Water Absorption (EN ISO 354) By Volume 2% (168 hours)

• Closed Cell Percentage (EN 14509) %95

• Vapour Diffusion Resistance (EN 12086) 30-100

• Heat Resistance -200 /+110 ºC

• Prepainted Galvanized Steel Surface Type Prepainted Galvanized Steel

• External Facing Thickness 0,50-0,8 mm

• Thickness Tolerance (EN 10143) Nominal

• Steel Quality (EN 10327) Dx51 D+Z Prepainted Galvanized Steel (last coat polyester paint on primer

• Hot Dipped Coated Steel Grade (EN 10327) 100-275 gr/m2

• Paint Type Polyester, PvdF, Plastisol, PVC

• Aluminum Steel Surface( Type Aluminum

• External Facing Thickness 0,50-0,70 mm

• Internal Facing Thickness 0,40-0,70 mm

• Thickness Tolerance (EN 485-4) Nominal

• Steel Quality (EN 485-2) High Conditioned AW 3000 series aluminum manufactured by Assan Aluminum

• Condition (EN 485-2) H16-H26

• Alloy (EN 485-2) AW 3000 series

• Surface Appearance Embossed or Prepainted

• Temperature Resistance -200 /+110 ºC

• PVC Membrane Thickness 1,2 mm

• Unit Weight on Field 1,55 kg/m2 ±5%

• Tensile Strength ≥500 N/cm

• Puncture Strength ≥450

• Alongation at Break ≥80%

• Tensile at 80 o

• C after 6 hours ≤-0,1%

• Behaviour Under Hydrostatical Pressure, at 2 bar 24 hrs Impermeable

• Accelerated Ray Aging at 80 o

• C ≤-2,5%

• Standard Appearance Light grey, matte

ISO 9001, ISO14001, ISO27001, Efectis Era 60 Min. Test Certificate, Certificate of Conformity to Turkish Standards

- 1 - N5M Roof Panel Technical Data Sheet

- 2 - ISO 9001 Certificate

- 3 - ISO 14001 Certificate

- 4 - ISO 27001 Certificate

- 5 - Efectis Era 60 Min. Test Certificate

- 6 - Certificate of Conformity to Turkish Standards

- 7 - Assanwool, AssanPU, AssanIron & AssanBoard Catalog

- 8 - Assan Panel Prefab Housing Solutions

- 9 - Assan Panel Building Envelope Solutions

- 10 - Assan Panel Brochure

- 11 - Assan Panel Catalog

- 12 - AssanChem Continuous Panel Systems