Istanbul Airport

-

2018

ANIL FLOOR MARKET

Carpet tiles, linoleum, PVC flooring, mats, over 200,000 square meters in the Terminal I building of Istanbul Airport, one of Turkey's prestige projects, completed to serve more than 200 million passengers annually at Istanbul Airport, the world's new and largest aviation center. Many floor covering applications such as systems, self leveling, YDS (Raised Floor Systems) were carried out by the Anıl Floor Market team.

In an area of 35,000 square meters, which includes the waiting areas, offices, bridges, playgrounds, logistics areas or duty free zones of Terminal I, which covers an area of 1.3 million square meters; Marmoleum Real, Sarlon 15 dB and Sphera Element collections in the linoleum, homogeneous and heterogeneous PVC flooring product categories were preferred. With the Tessera Alignment carpet tile collection in 4 different colors specially designed for Istanbul Airport, an application was made on 61,000 square meters, which also includes open and office areas. Along with Tessera Alignment, Flotex Metro collection was preferred in the bridge and FLB areas covering an area of 50,000 square meters.

ŞİŞECAM

In the Istanbul Airport project, which is among the mega projects; Glass combinations that meet all the needs of safety and security as well as noise control, heat insulation, effective solar control and optimum light transmission are designed with the Temperable Solar Low-E product developed specifically for the project.

In most of the project, on the exterior windows; 6+1.52+6 part is tempered laminated, in interior glass; By using 6+1.52+8 partially tempered laminated glass, 51% light transmittance, 29% solar factor and 41 dB noise control were achieved.

Şişecam Temperable Solar Low-E Glass Neutral 41/27, which is preferred in the large-surface roof skylights of the project where solar control is needed most, provides effective solar control with its high performance, allowing only 26% of the solar energy to enter on the roof, thus saving on cooling costs, while saving on cooling costs. Compared to double glazing, it reduces heat losses by 50 percent and lowers heating costs in winter. In addition, thanks to its 40% light transmittance, it makes it possible to watch the sky and clouds without giving up the luminous interior effect. Laminated glass, which is preferred in the interior glass combination, meets the security needs.

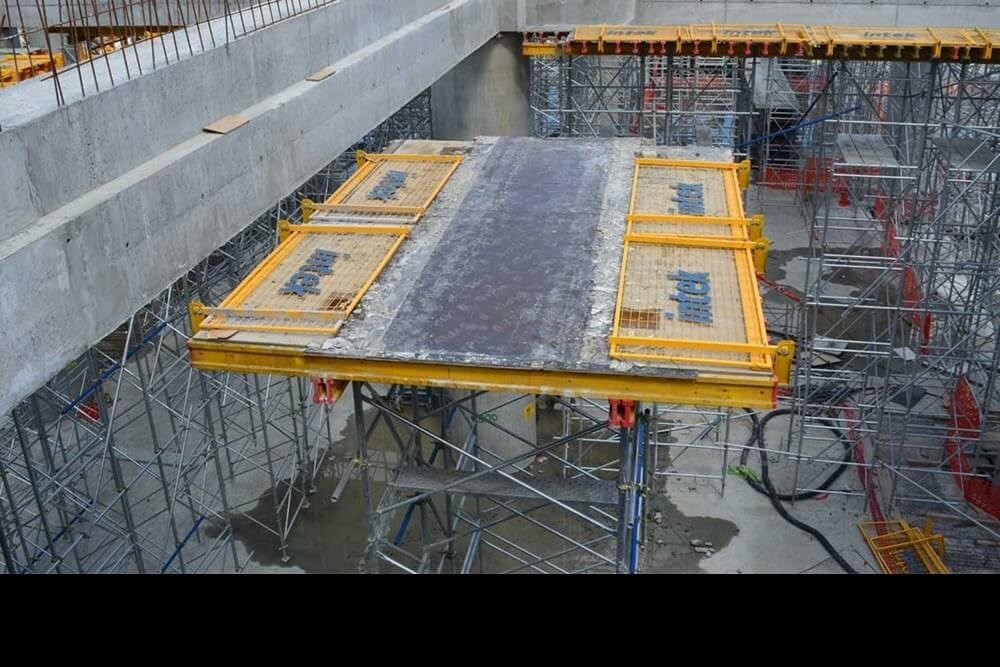

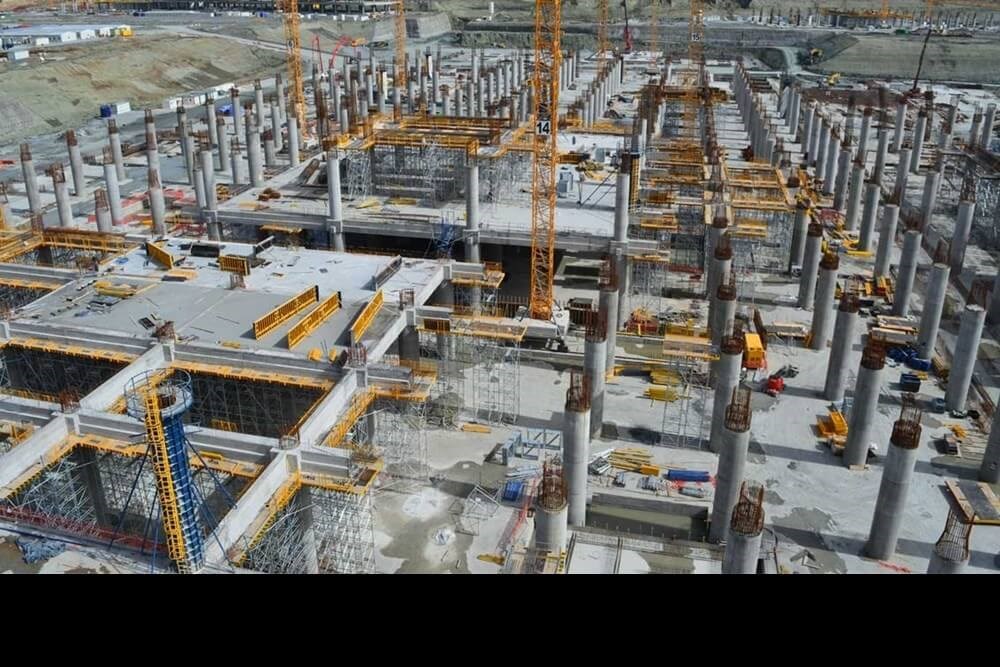

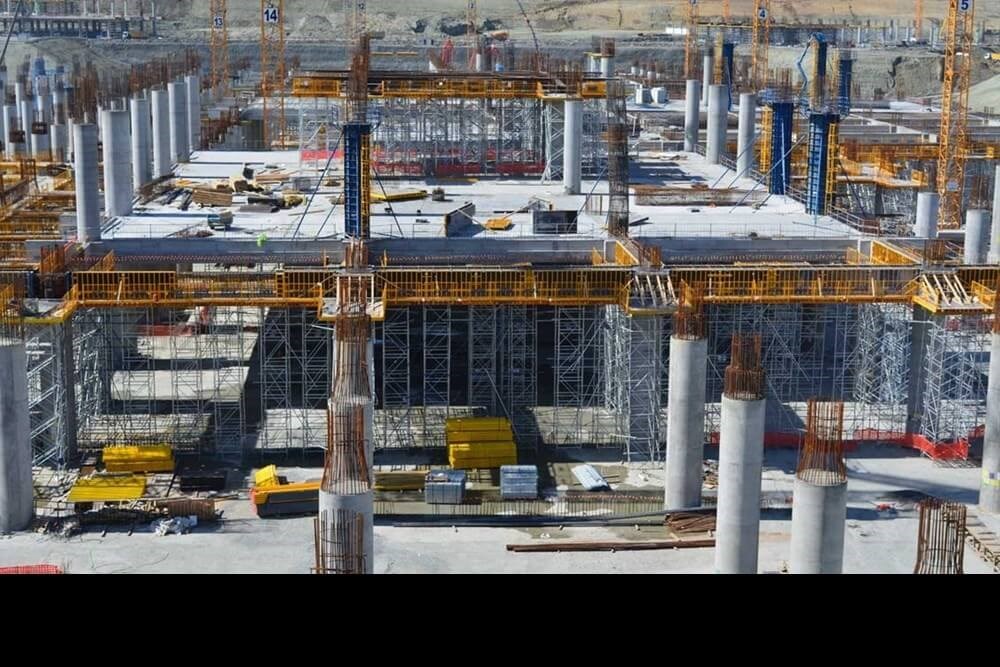

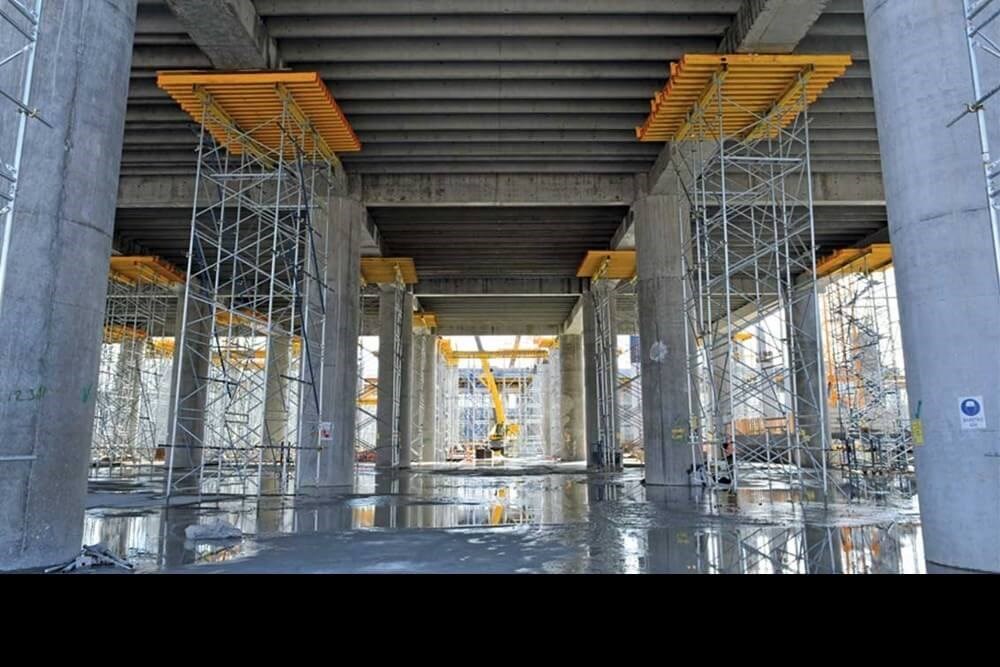

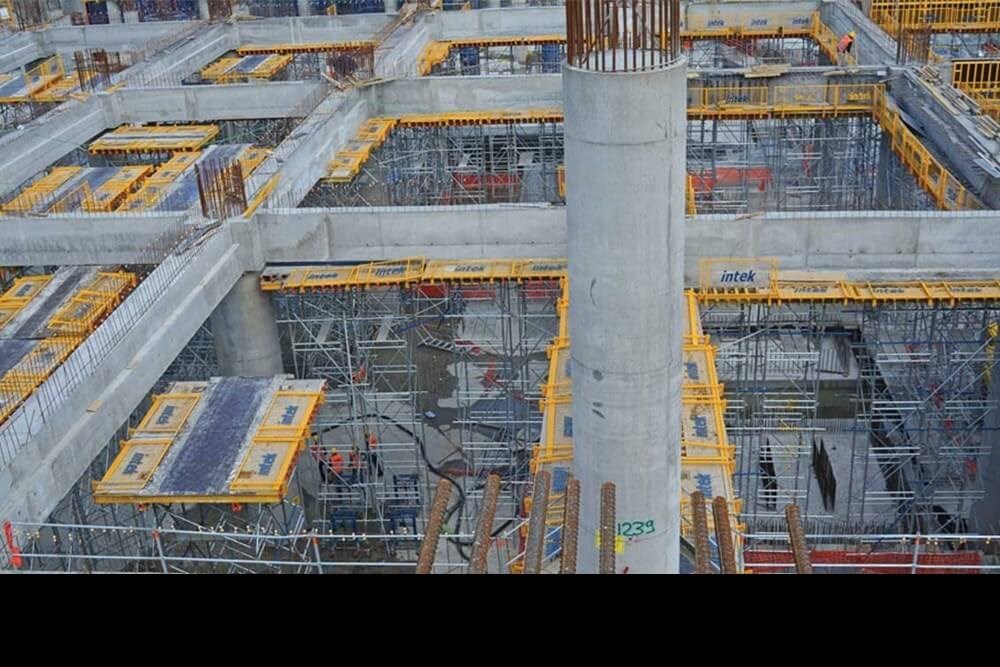

İNTEK

The New Airport, which will further carry Turkey's role in the international aviation market, was built on an area of 76.5 million m² on the European side of Istanbul, between the villages of Tayakadin and Akpınar on the Black Sea coast. Istanbul New Airport, which will consist of three terminals and six runways with an annual capacity of 200 million passengers, has been completed in four phases. In the first phase, three independent parallel runways, taxiways, apron, terminal building, air traffic, communication and meteorology systems and other service buildings. has been implemented. The first passenger terminal building, with 1.3 million m², is the largest terminal building in the world under a single roof, and this terminal serves 90 million passengers annually in the first stage. In the later phases of the project, this capacity has increased to 150 million passengers with additional terminal buildings and runways. Necessary planning has been made with the expectation that the airport terminal capacity can be expanded up to 200 million passengers in the long term. The rough construction of the 1.3 million m² “terminal building” and the “TB1” and “TB3” areas of approximately 456,000 m² were carried out by VMK. The rough construction of the "PB2" section of approximately 56.000 m² of the "pier buildings", which is divided into five sections in total, was carried out by the Biha-Tevaz Ordinary Partnership. VMK and Biha-Tevaz companies preferred İNTEK as their solution partner for formwork and scaffolding systems. The flooring system of the Terminal Building consists of cast-in-situ beams and prefabricated floors. HD 150 table system and PANEMAX panel formwork system were used in the cast-in-place beams of the project, which has a very large storey height of 12 meters. The "foldable guardrails" mounted on the tables have added a great deal of work safety and speed to the system. Circular columns with a diameter of Ø200 and Ø150 cm and a height of 11.40 meters were made very quickly by daily concrete casting thanks to INTEK designs, which simplifies and accelerates the operations and at the same time prioritizes work safety.

QUBI

Qubi contributed to the THY Support Facilities included in the project with U22, VC2100, firefoam, acoustic heavy barrier, DA3, DA1 products.

TACER

Istanbul Airport enriches national and international cultural values with its extraordinary architecture and innovative technical solutions. The production and assembly process of Tacer Troyaline Baffle Suspended Ceiling Systems, which were analyzed and produced specifically for the Istanbul Airport project, was carried out by Tacer’s expert team. In this impressive airport project, Tacer Baffle Suspended Ceiling Systems blended high acoustic performance into the gracefulness of the structure. The materials of the building elements and tools used in the structure were produced from sustainable raw materials, and the project was conducted in a nature-friendly manner. Thanks to Tacer’s fire-resistant production method, the systems, which are produced environmentally friendly, also prioritize human-centered security measures and take the safety of Istanbul Airport one step further. Tacer is glad to announce that Tacer Baffle Suspended Ceiling Systems were selected to be utilized in the construction of this magnificent structure, which has now become Istanbul's newest landmark.

The vaulted design extending from the floor to the ceiling in the interior gives visitors a strong sense of direction. Moreover, the layout created during the design process strengthens the flow of the interior space and creates a structure that allows visitors to experience a visual feast. Besides, roof windows which are built alongside the Tacer Baffle Suspended Ceiling Systems allow the sunlight to filter into the interior spaces. Thus, the interior space illuminated by daylight gained a splendid visual quality owing to the refraction of the sunlight and perfectly implemented Baffle Suspended Ceiling Systems.

The varying tones of Istanbul's urban image have been used to inspire the interior design of Istanbul Airport. The effect of daylight on the interior, the blue color spectrum formed in the interior space and the patterns formed by the shadows falling on the ground are entirely generated by the help of Tacer Baffle Suspended Ceiling Systems. Also, the tiered design of the Baffle system components on the upper levels brought aesthetics and functionality together. The geometric design pattern of the ceiling system pays homage to the city's architectural heritage while also being backed up by a thorough structural analysis performed by Tacer's professional technical team.