Louver Building Components

Please click on "Offer Request" button below to send your offer and detailed information request to the company for the Louver Building Components product.

- Facade Cladding: Louvers are used in building facades to provide an aesthetic appearance and control sunlight. They also contribute to increasing the energy efficiency of buildings, helping create a more comfortable environment indoors.

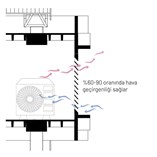

- Ventilation Systems: Louvers are used in ventilation systems to direct airflow and improve indoor air quality. By enabling natural ventilation, they contribute to energy savings.

- Windows and Doors: In window and door systems, louvers help control the amount of direct sunlight entering, assisting with temperature regulation inside. They also provide privacy by limiting external visibility.

- Shading and Sun Protection Systems: Louvers are used in shading systems to control the intensity of sunlight, preventing overheating in interior spaces and improving natural lighting conditions.

- Commercial and Industrial Buildings: Louvers are applied in commercial and industrial buildings, particularly in large factories, warehouses, and office buildings, to optimize airflow and enhance indoor comfort.

- Outdoor Designs: Louvers can be used in outdoor spaces such as gardens, terraces, and pool areas to provide privacy and create visual barriers.

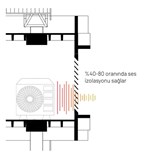

- Acoustic Insulation and Noise Control: Louvers can be used in interior spaces, particularly in areas where noise reduction is important. The arrangement of the slats can help absorb sound waves.

• Material: Louvers are typically made from materials such as aluminum, stainless steel, wood, plastic, or composite materials. Aluminum and stainless steel provide durability and long lifespan, while wood offers an aesthetic and natural appearance.

• Blade Spacing and Gap: The spacing and gap between the louvers' blades regulate airflow. Blade spacing allows light transmission and air circulation while also offering visual privacy. These measurements can be customized to meet the specific needs of the application.

• Angle of Inclination: The angle of the louvers’ blades plays a crucial role in directing sunlight and rainwater. Typically, they are manufactured with an angle range of 15° to 45°, but custom angles can be designed for specific projects.

• Dimensions: Louvers are available in standard and custom sizes. Common widths range from 600 mm to 1200 mm, and common heights range from 600 mm to 2400 mm. However, custom dimensions can be provided based on project requirements.

• Surface Finish: Louvers are often coated or painted to provide protection against corrosion. For aluminum louvers, anodized coatings or polyester painting are commonly used, while stainless steel louvers may feature brushed or polished surface finishes.

• Durability: Louvers must be resistant to environmental elements, particularly for outdoor applications. They need to be durable against weather conditions, UV rays, humidity, and salty air. Materials like stainless steel and aluminum offer the necessary resistance.

• Airflow and Light Control: Louvers optimize airflow while limiting direct sunlight entry, helping regulate the light levels in the interior. They also help prevent unwanted temperature increases due to sunlight penetration.

• Acoustic Performance: The sound insulation capacity of louvers depends on the material used and the design of the blades. Properly placed and designed louvers can reduce noise and create a quieter indoor environment.

• Fire Resistance: Some louvers are made with fire-resistant materials, especially in industrial and commercial buildings, to enhance fire safety.

• Installation and Maintenance: Louvers are designed to be easy to install and typically require low maintenance. Their surfaces are easy to clean, and regular upkeep ensures long-lasting performance.